Bone

Products

-

Preoperative simulation

Implant Treatment

The depth and angle of the implant can be confirmed in advance.

More Details

-

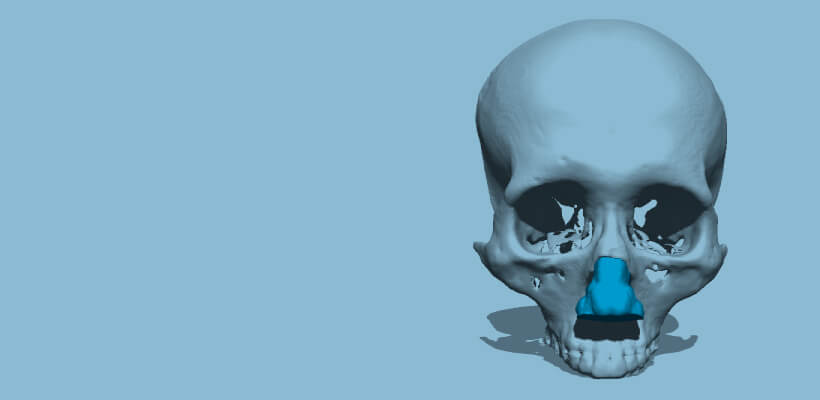

Preoperative simulation

Cosmetic surgery, Nose

A cranial model that can reproduce the cartilage part of the nose can be simulated in advance.

More Details

-

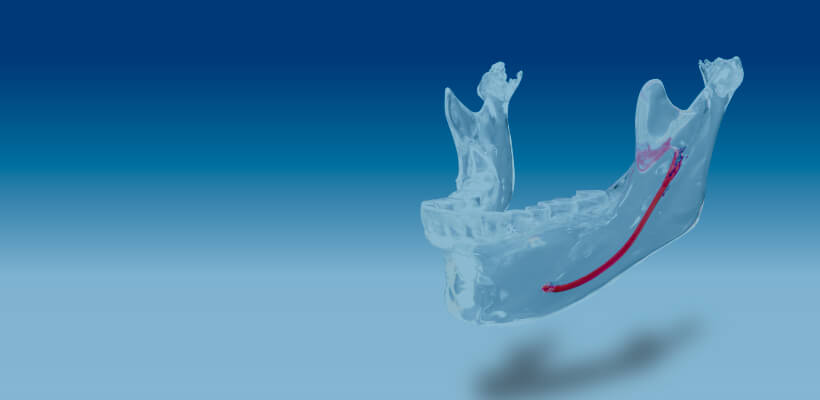

Preoperative simulation

Facial contouring,

Inferior alveolar canal

The osteotomy line can be drawn while checking the position of the inferior alveolar nerve canal.

More Details

-

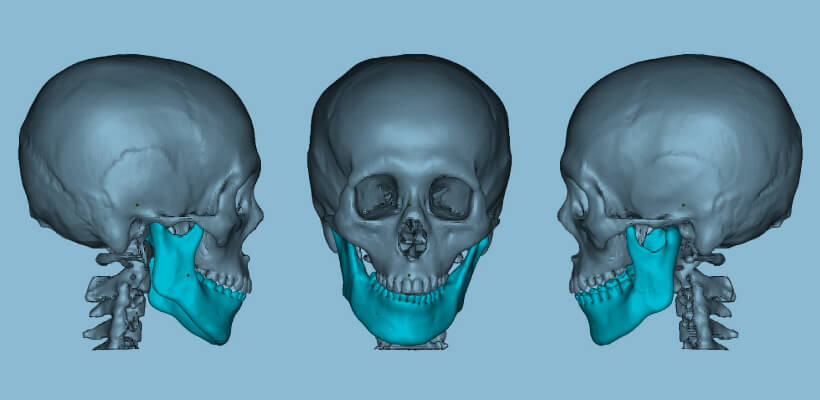

Preoperative simulation

Jaw deformity

Preoperative fixation simulation allows for verification by inserting the actual device.

More Details

-

Preoperative simulation

Skull

A full-scale model of the skull can be created from CT data.

More Details

-

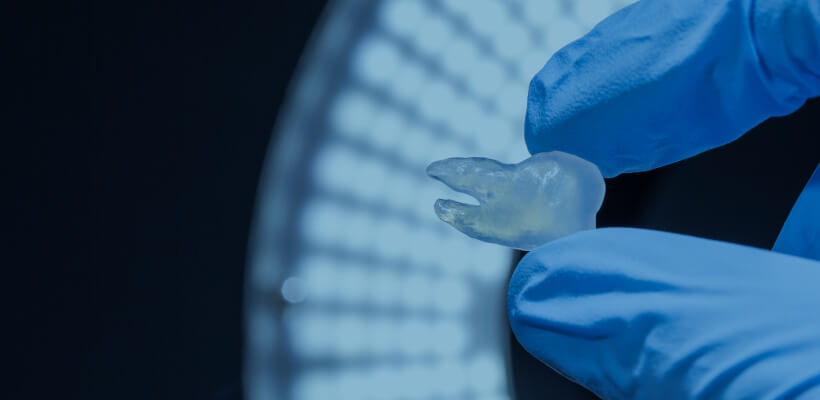

Preoperative simulation

Tooth transplant

Wisdom teeth for grafting can be simulated before the surgery.

More Details

-

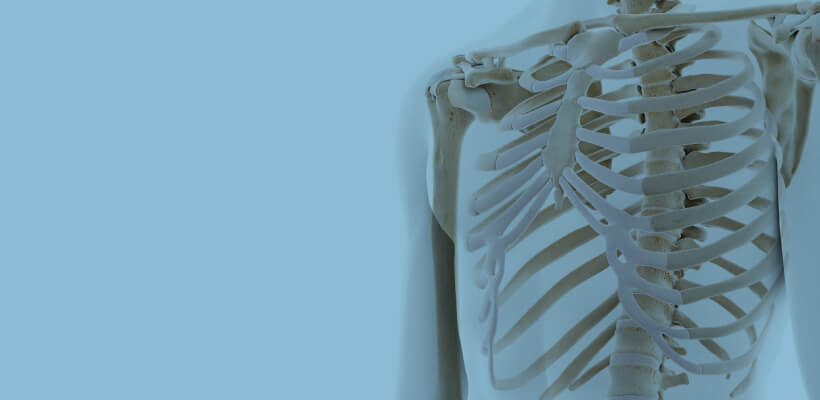

Preoperative simulation

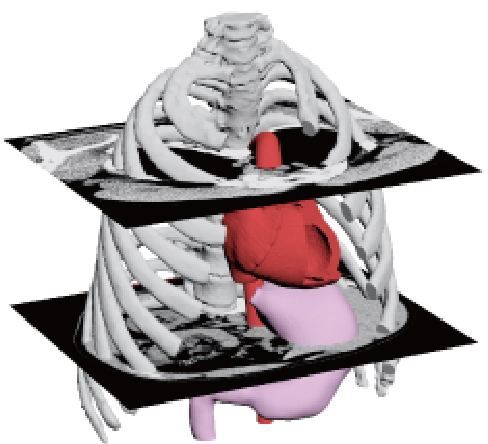

Sternum

A full-scale model of the patient, such as a sternum fixation surgery, can be used for preoperative verification.

More Details

-

Preoperative simulation

Humerus

Full-scale models of osteosynthesis and other procedures can be used to verify the degree of fixation.

More Details

-

Preoperative simulation

Spine

A full-scale model of the patient's spine can be used to verify fixation before surgery.

More Details

-

Preoperative simulation

Radius

The implant placement process can be verified preoperatively, including osteotomy, drilling, and fixation.

More Details

-

Preoperative simulation

Pelvis

We can verify the fixation of the plate and the position of the graft before the surgery.

More Details

-

Preoperative simulation

Femur

Preoperative verification of the position of the graft, such as osteosynthesis and artificial head insertion.

More Details

-

Preoperative simulation

Tibia

Preoperative confirmation of the depth and angle of rate and screw implantation.

More Details

We will provide you

with the best proposal in terms of price

and quality to meet your needs

From CT imaging to 3D printing

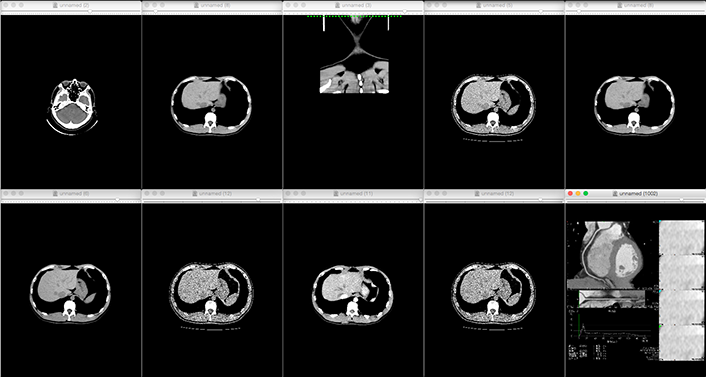

In recent years, the evolution and widespread use of dental CT and medical CT has made it possible to obtain data (dentition and skeletal structure) from patients themselves, and by processing the data obtained from CT imaging and outputting it to a 3D printer, preoperative simulations can now be performed on full-scale models. With a full-scale model in hand, the treatment team can share information about the fit, which is not possible on a CAD screen, and formulate an advanced treatment plan.

-

Reads DICOM data obtained from CT imaging into mimics

-

Eliminates noise (artifacts) generated by metal and other materials

-

We will convert the data into 3D data

and confirm with the customer that the area of interest has been

reproduced in the image or data*If the STL output is available directly from the medical workstation,

the above process is eliminated. -

3D printing output

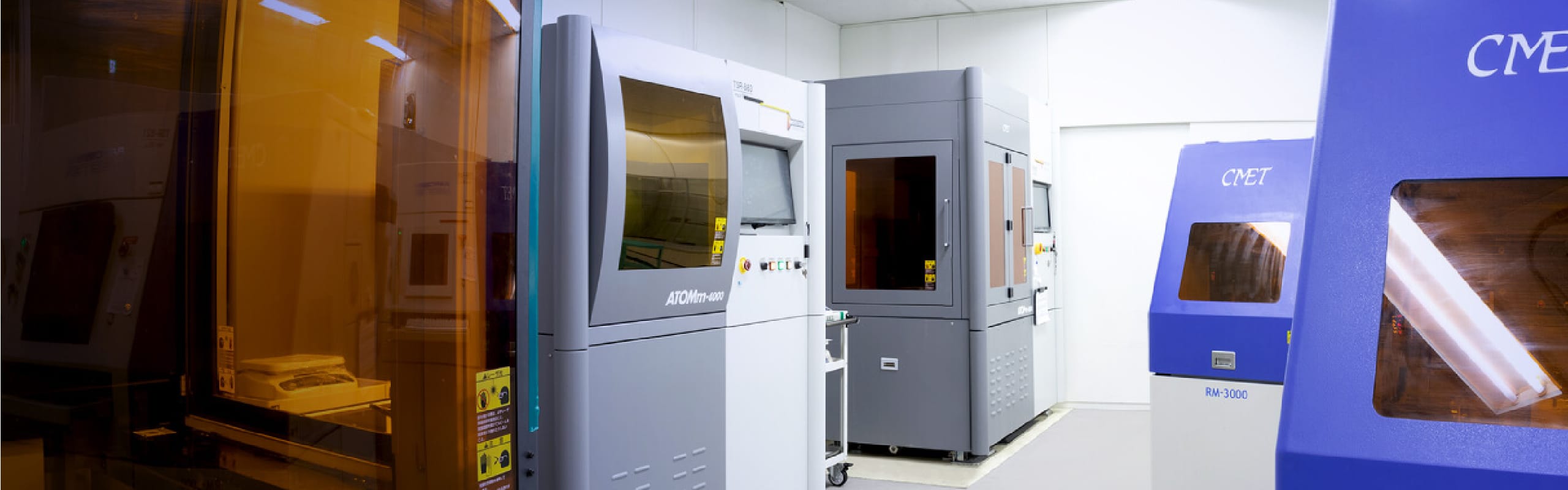

Use of 3D Printers

While most of the models for verification of medical devices used to be made of plaster, in recent years, there has been an increasing demand for soft and transparent models that are closer to the human body. Silicon materials can now reproduce blood vessels, nerves, and cartilage of the nose of the living body, and epoxy light-curing resin materials can be used to make transparent models, so that the inside of the model can be visually checked and the procedure can be confirmed in real time. The bone model can be used not only by medical professionals to confirm procedures and formulate treatment plans through preoperative simulation, but also by medical device manufacturers as a development tool, sales promotion tool, marketing tool, and internal training tool. It can also be used as a development tool for medical device manufacturers, a sales promotion tool, a marketing tool, and an internal training tool.