Implant Treatment

Preoperative simulation

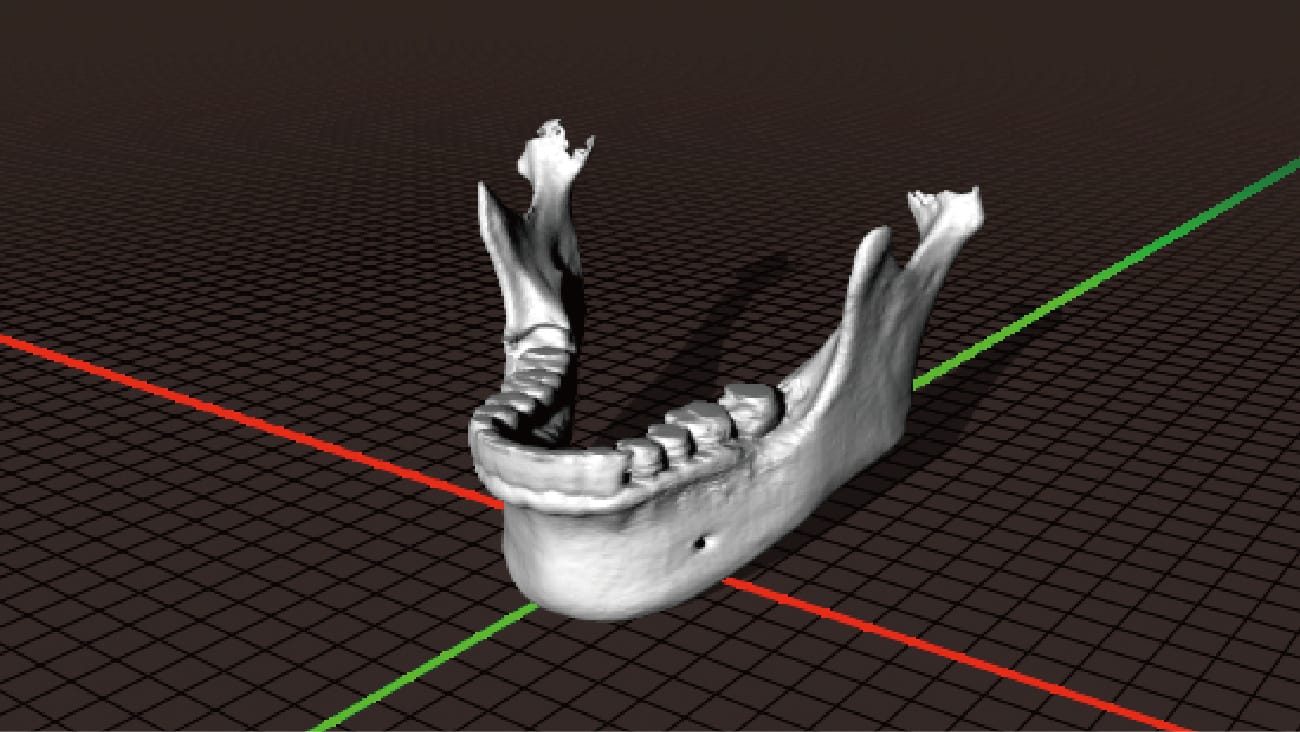

Utilizing 3D Printing for Implant Treatment

An implant is a surgical procedure to replace a tooth that has been lost due to some accident with an

artificial tooth root. In many cases, dental casts are used for dental treatment. A dental model is made

by taking a mold of the patient's teeth and inverting it into plaster.

The merit of this method is that it is possible to take a highly accurate model of the patient's teeth

because a mold is taken directly from the patient and inverted. However, the skeletal structure of the

maxillary and mandibular bones could not be grasped due to the presence of skin and gums. Implant

Treatment is a procedure to implant artificial tooth roots into the bone, so the shape and mass of the

bone must be grasped in detail.

In recent years, the evolution and widespread use of dental CT and medical CT has made it possible to

obtain data (dentition and skeletal structure) from patients themselves, and by processing the data

obtained from CT imaging and outputting it to a 3D printer, preoperative simulations can now be

performed on full-scale models. With a full-scale model in hand, the treatment team can share

information about the fit, which is not possible on a CAD screen, and formulate an advanced treatment

plan.

Advantages of Using 3D Printers

in Implant Treatment

There are four major advantages to confirming the depth and angle of implant placement in advance.

-

Shorter treatment time

-

Improvement of treatment accuracy

-

Reducing the burden

on patients -

Improvement of techniques

Main uses

- Confirmation of procedures and treatment plans

- Checking the fit of the implant to be placed

- Tools to explain to patients (informed consent)

- Development tools, sales tools, and marketing tools for medical device manufacturers

Supported Materials

- Epoxy resin

(optical molding) - Nylon

- Silicon

More Details on Materials