Vascular IVR

Products

From CT imaging to 3D printer output

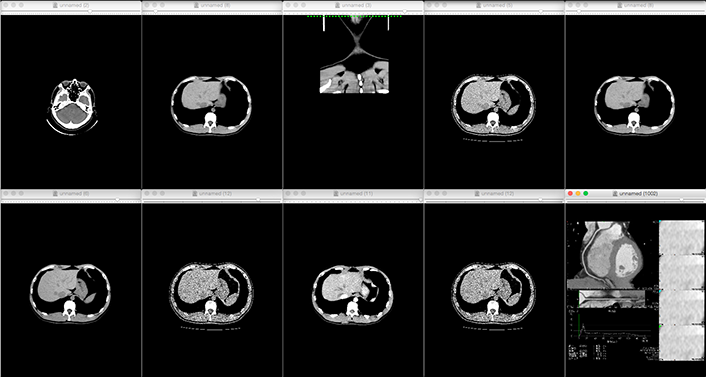

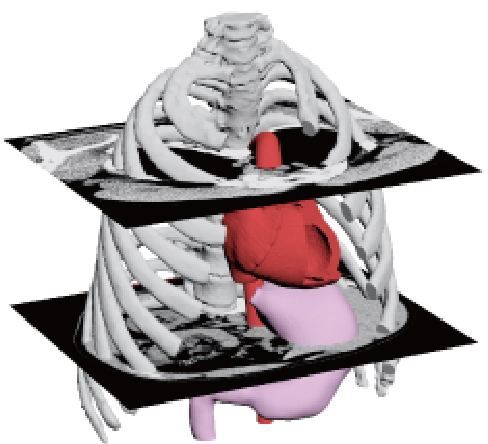

- Reads DICOM data obtained from CT imaging into mimics

- Eliminates noise (artifacts) generated by metal and other materials

-

3D data is converted to images or data to see if the region of interest is

We will confirm with the customer that the area of interest has been reproduced.

The customer will be asked to confirm that the area of interest is reproduced in the image or data.If the STL output is available directly from the medical workstation, the above process is eliminated.

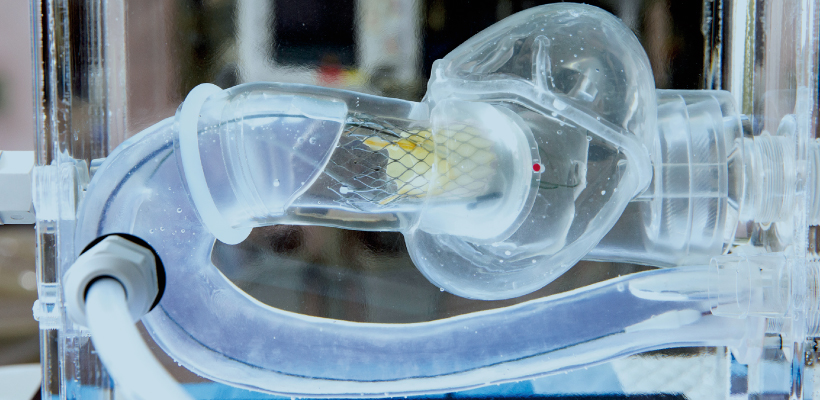

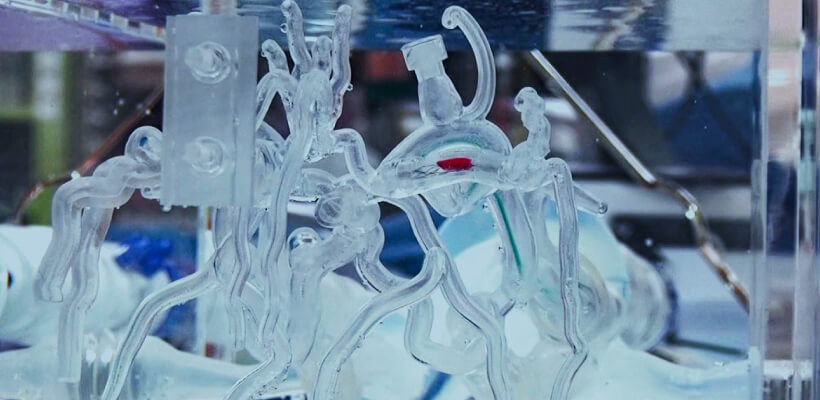

- 3D printing