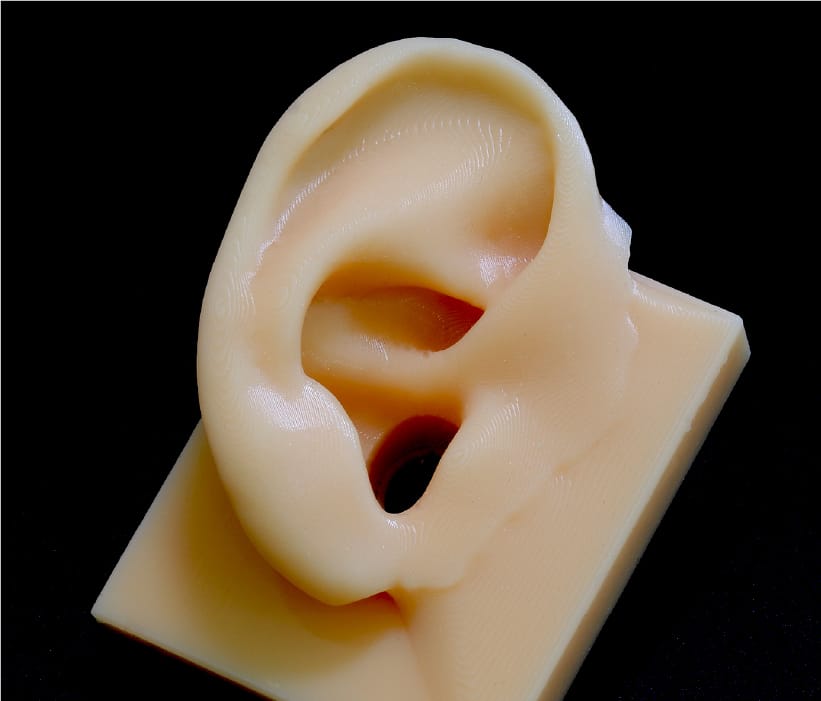

Simulator

customization

More updates to

your medical simulator

Editing JMC data

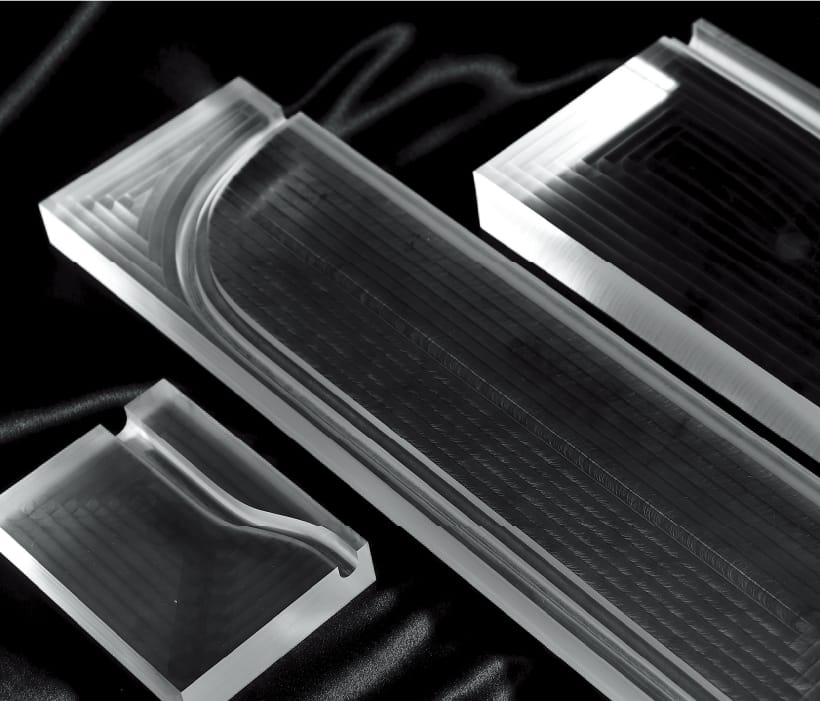

List of supported materials

Order and Repair Flow

-

1

Apply through the inquiry form.

Please use the contact form below to apply.

-

2

Our company will call you.

We will have a brief interview with you by phone.

We will take back the product to be repaired and carefully inspect the defective part.

-

3

Repair methods and estimates

After 3 business days of investigation, we will inform you of the repair method and estimate.

-

4

Manufacture and repair

We can repair and manufacture in the most appropriate way using all kinds of materials.

-

5

Delivery of products

If this is your first transaction, you may be asked to make a deposit in advance.