Industrial CT scan

JMC Lab approach with industrial CT

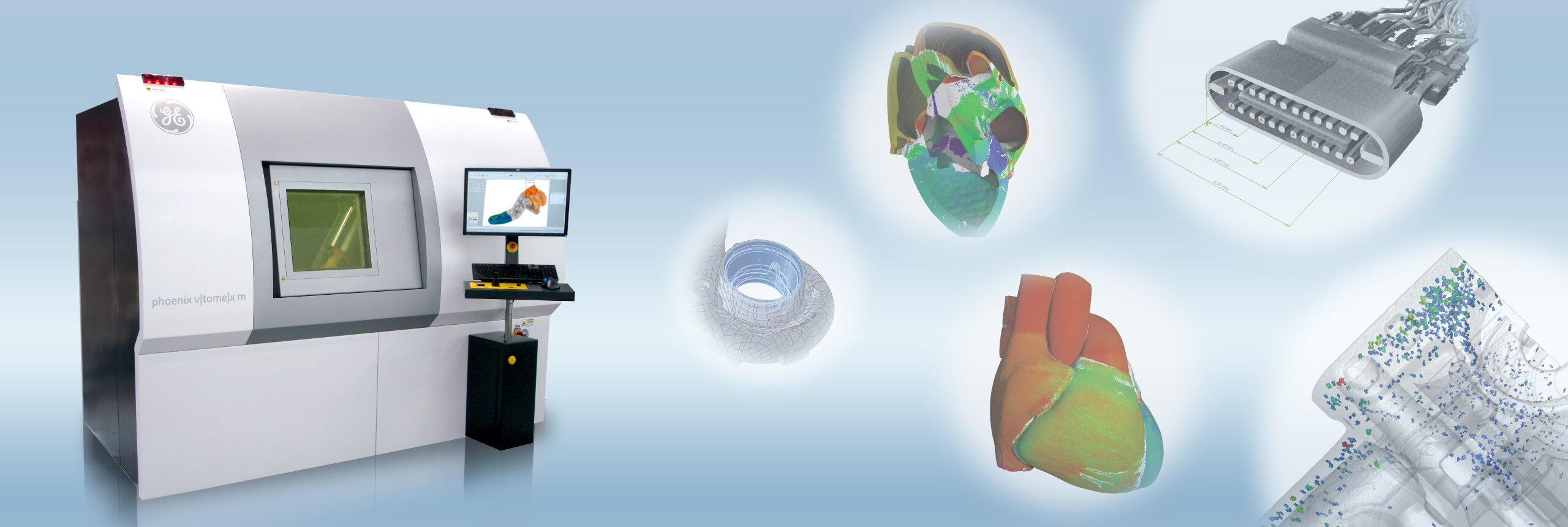

JMC has one of the largest industrial CT scan facilities in Japan and conducts more than 10,000 scans per year, giving us an unparalleled track record and expertise in inspection and measurement. JMC also applies this technology to medical simulators, providing services such as the creation of models that faithfully reproduce the structure of the actual human body, and the repair and improvement of all simulators on the market.

Differences between industrial CT and medical CT

X-ray CT scanners are categorized into "medical" and "industrial" scanners, and these two types of scanners

are designed very differently due to the differences in their applications.

In a medical CT scanner, the most important thing is to reduce the radiation dose because the scanner

captures images of a living body, and the X-ray tube and detector rotate around the body to reduce blurring

of the body. The images are taken in a very short time using a high dose.

On the other hand, industrial CT scanners do not need to reduce radiation dose to image industrial products.

Instead, the X-ray tube and detector are fixed, and the rotating table on which the product is placed moves

to take long time images with low dose. As a result, industrial CT scanners are able to obtain high quality

data with high accuracy and low noise, and are used in various applications such as quality inspection of

industrial products, evaluation of developed materials, and reverse engineering of other companies'

products.

How to use an industrial CT scanner

High-precision 3D measurement

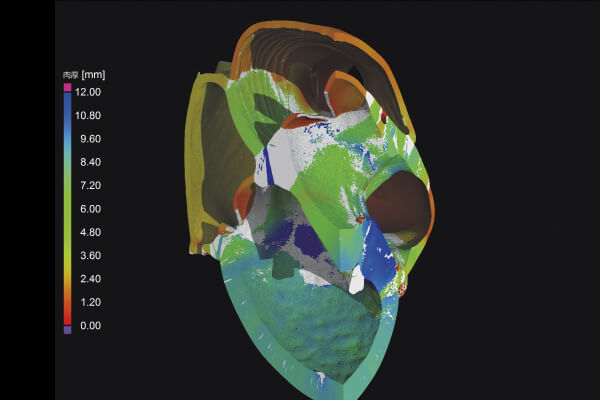

Unlike measurement methods that project visible light onto an object and measure the reflected light, CT scanners measure the light transmitted through an object, making it possible to acquire three-dimensional data on shapes such as undersides and depressions, as well as on metallic luster and transparent samples. In addition, since the system has a much higher resolution than medical CT, it can perform highly accurate scans that include the texture of the organ surface. By using this characteristic to measure biological samples such as organ specimens, it is possible to manufacture models and simulators with better reproducibility than before.

Simulator repair and customization

Many complex and elaborate models and simulators are still manufactured by hand and have many individual differences, making it difficult for the seller to repair them. By using high-precision industrial CT scans, JMC is able to analyze the structure of each product and perform the corresponding repairs. JMC is able to analyze the structure of each product using high-precision industrial CT scans and perform repairs.

Materials Research

JMC Lab's simulators not only reproduce shapes, but are sometimes designed for use in more practical environments, such as X-ray fluoroscopy in a cath lab. In such cases, the development of materials that enhance the reproducibility of fluoroscopic images is required, and we support the development of a wide variety of materials by utilizing the know-how gained from X-ray CT scans.