3D Pringting

Medical simulator using a 3D printer

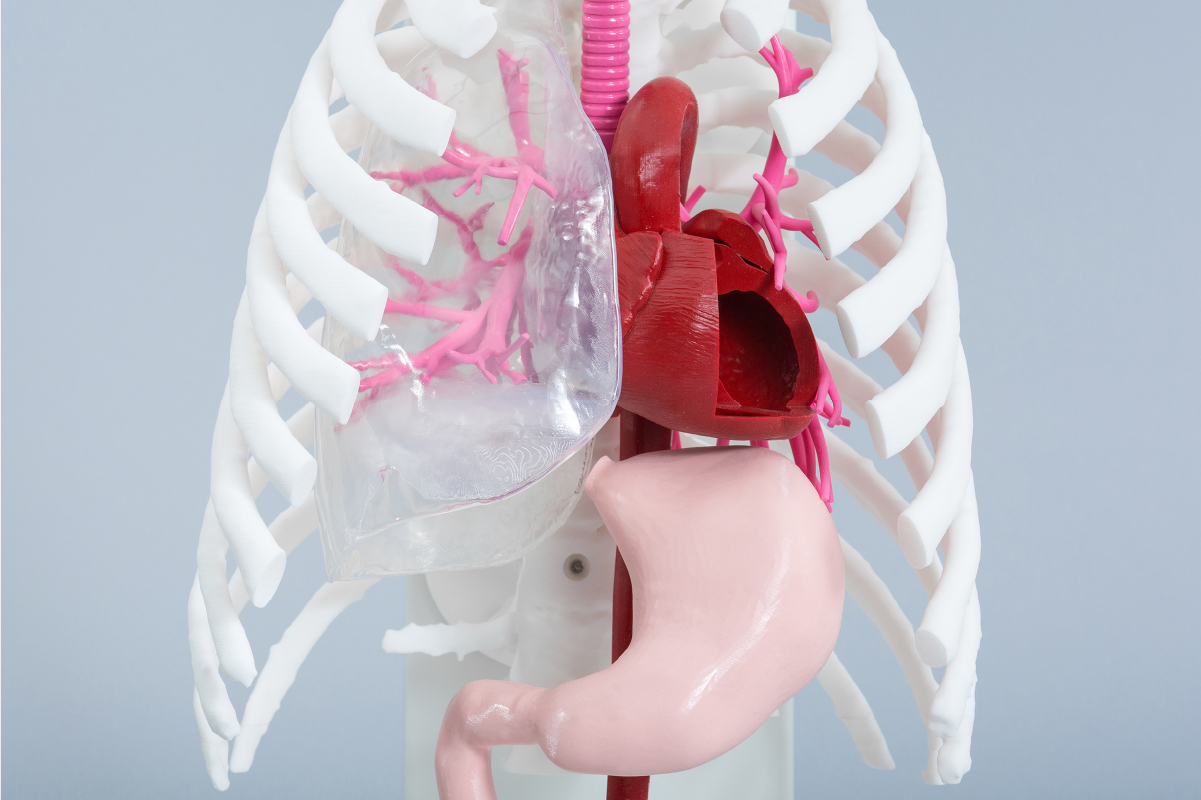

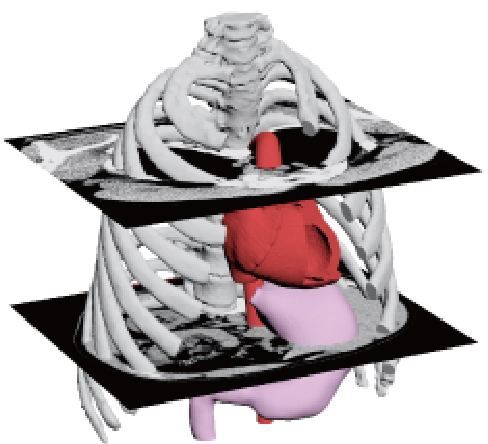

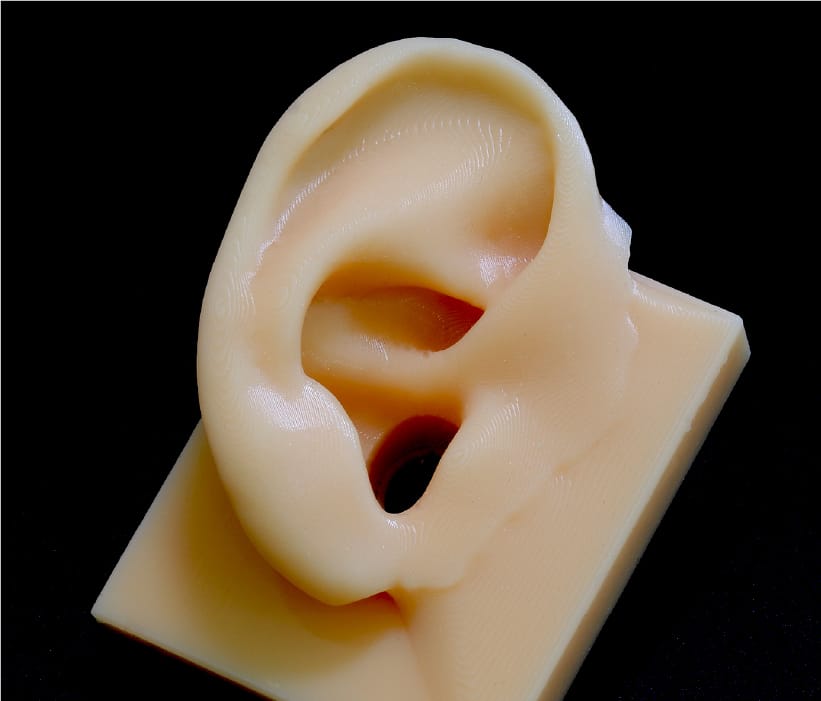

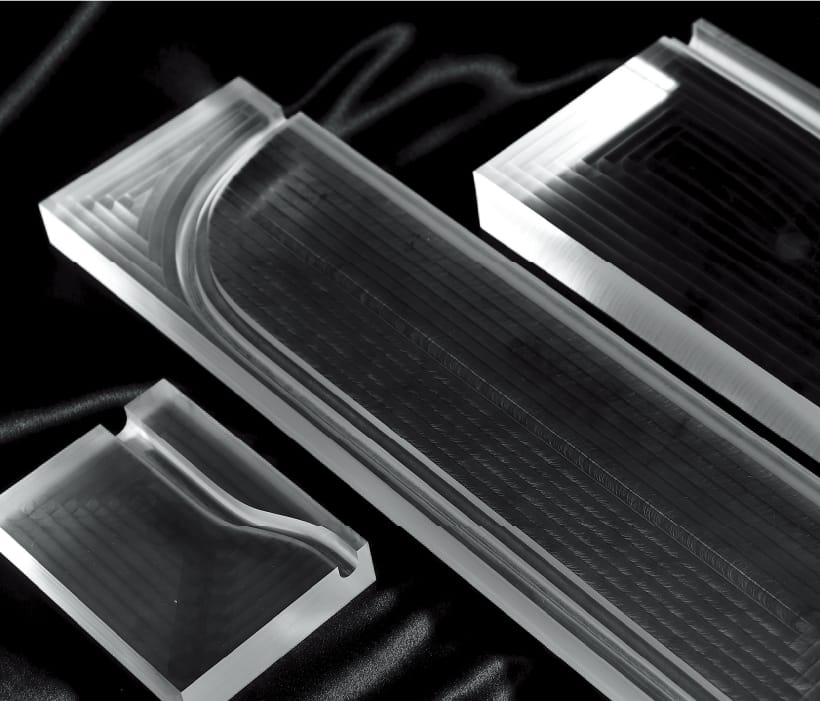

JMC's medical model fabrication service uses 3D printers and other digital technologies to achieve a high degree of freedom in model fabrication. 3D printed resin models are combined with vacuum casting technology to transfer the shape onto transparent, soft, and other materials. By combining 3D printed resin models with vacuum casting technology, we are able to transfer shapes onto transparent, soft, and other materials, providing services that thoroughly pursue the shapes, textures, and functions that customers demand.

JMC Technology

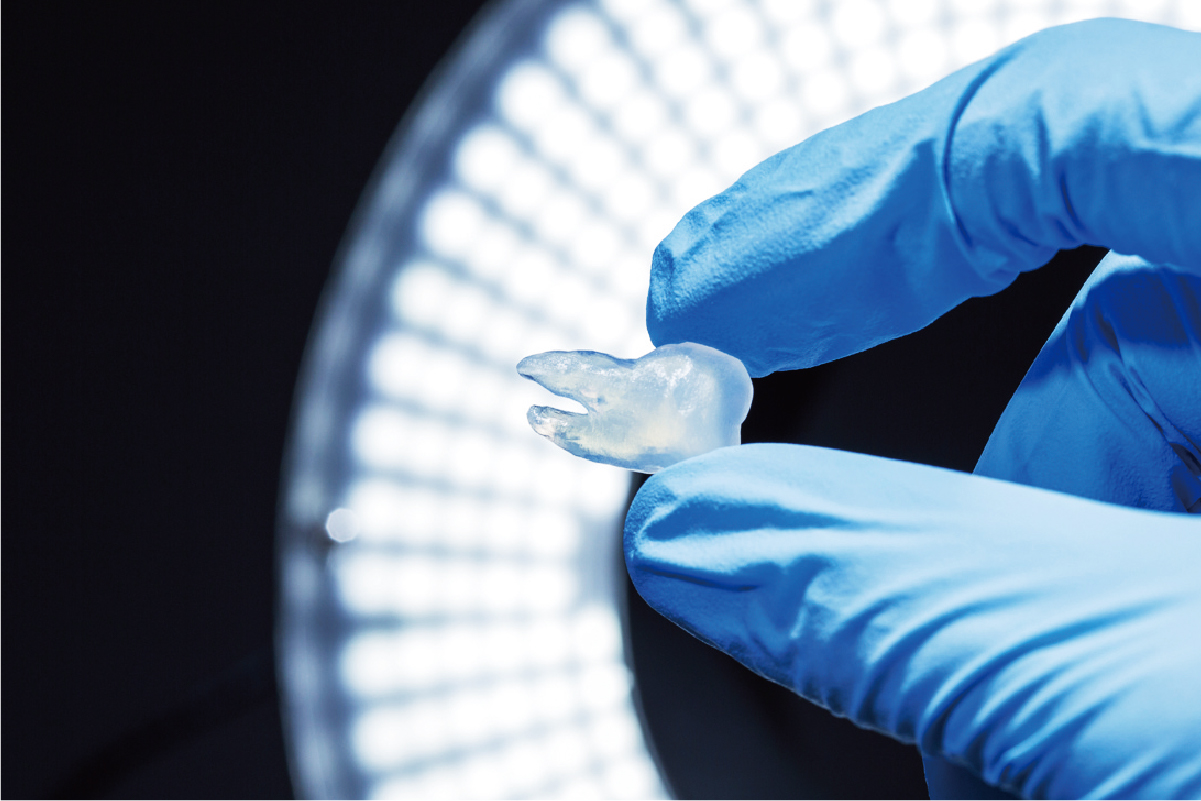

Soft model with unique technology

In general, soft models often fail to reproduce some shapes, such as simplifying the inside of organs, but JMC Lab possesses a unique technology that combines 3D printing and casting technologies to faithfully reproduce the outside and inside of organs. JMC Lab has a unique technology that combines 3D printing and casting techniques to faithfully reproduce the outside and inside of organs. This method allows for a higher degree of material flexibility than direct 3D printing of soft materials, and allows for adjustments in hardness, color, X-ray transmission, etc.

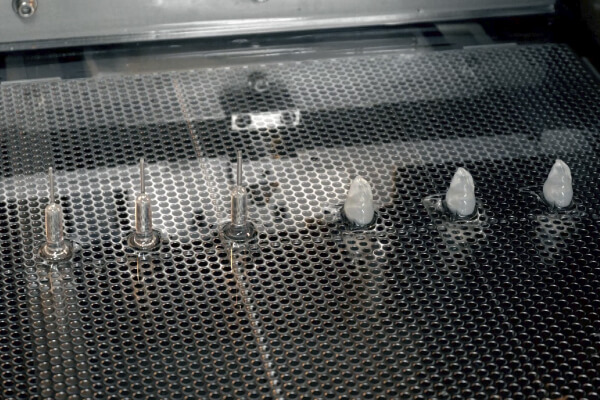

Rigid model with short delivery time

We have a system in place that allows us to work 24 hours a day, 7 days a week on rigid models that are output directly from the 3D printer, so that we can deliver them quickly to our customers in fields that require speed, such as preoperative simulation and prototyping of medical devices. We have a variety of output methods, including optical, SLS, and inkjet, so you can choose the most suitable method for your application.

Soft organ model

One of the strengths of JMC's medical entity models is the ability to produce soft models. However, JMC's unique know-how and painstaking manufacturing methods enable us to accurately reproduce the complex shapes of organs and to adjust the hardness according to the part to be manufactured. JMC's unique know-how and labor-intensive manufacturing methods enable us to accurately reproduce the complex shapes of organs and adjust the hardness of the parts we manufacture.

All models are customizable.

JMC all of our models are made to order. In addition to directly sculpting the customer's 3D data, we can also customize the data and create data from CT and MRI. Even if you do not have any original data, we can make a proposal to realize your image based on your sketch.

Data editing

Model Surgery

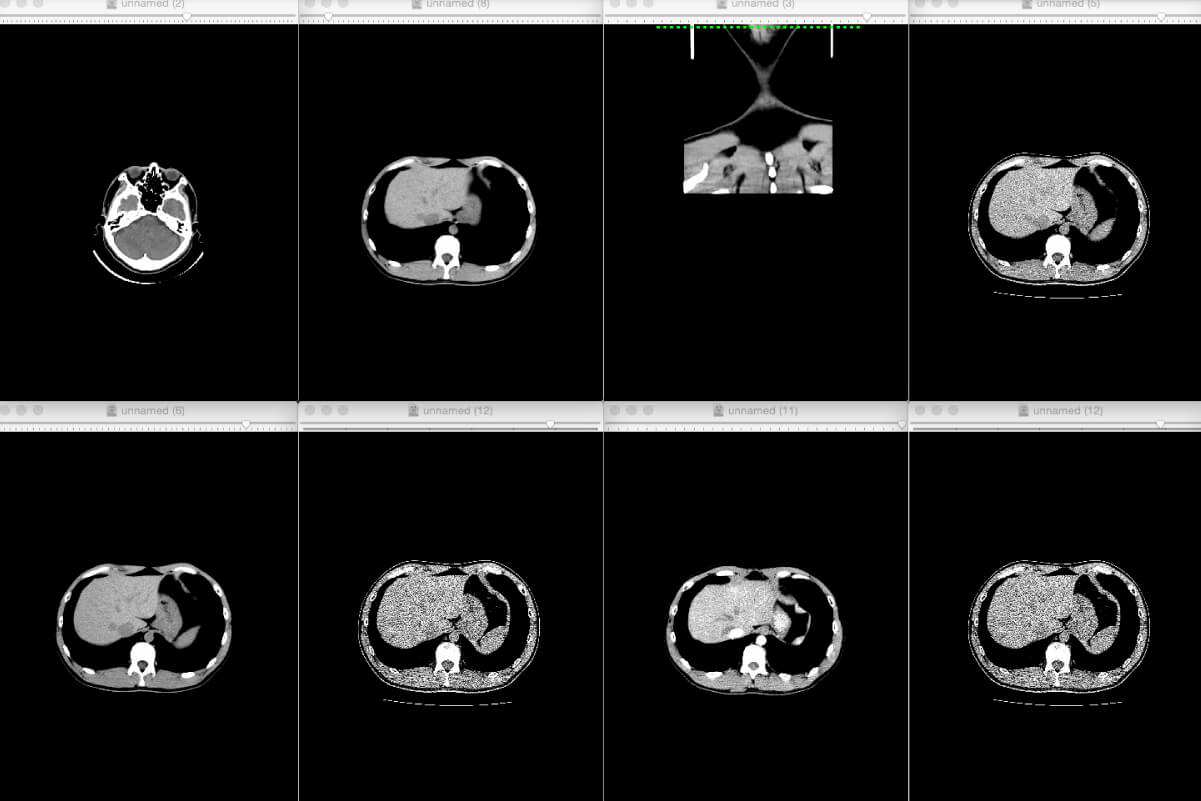

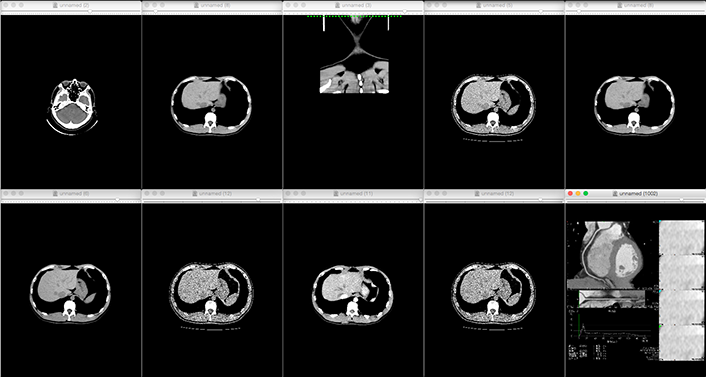

- Reads DICOM data obtained from CT imaging into mimics

- Eliminates noise generated by metal and other materials

-

3D data is converted to images or data to see if the region of interest is

We will confirm with the customer that the area of interest has been reproduced.

The customer will be asked to confirm that the area of interest is reproduced in the image or data.If the STL output is available directly from the medical workstation, the above process is eliminated.

- 3D printing

About DICOM data

DICOM, which stands for Digital Imaging and COmmunication in Medicine, is the name of a global standard used for the storage and communication of medical images. DICOM was originally developed by the American College of Radiology (ACR) and the North American Electronics Manufacturers Association (NEMA) in 1985, and was renamed DICOM in 1993. In 1993, the name was changed to DICOM, and it came to be used as a standard. In Japan, it was officially recognized as a standard by the former Ministry of Health and Welfare in 1999. JMC can produce high-precision medical models by using DICOM data captured by CT scans and MRIs. Depending on the target area, a model with high reproducibility can be produced if slice images with a pitch of 1 to 2 mm are provided.

3D data extraction from medical CT and MRI data

3D data is essential for the production of models using 3D printers, but it is not always possible to

prepare 3D data in the medical field. In such a case, if you can provide us with DICOM data obtained from

CT or MRI, we can create precise 3D data.

JMC uses a software called "mimics" to construct precise skeletal and organ shapes from DICOM data. JMC

uses mimics software to construct precise shapes of skeletons and organs from DICOM data. By having

specialized engineers perform image processing using mimics, it is possible to extract only the areas of

interest and output higher quality 3D data with less distortion caused by metal products such as gold

teeth and pacemakers.

Supported materials

-

rapid prototyping (machine)

Complex shapes can be integrally molded in a short time. Since the liquid resin is cured by the laser one layer at a time, the "corner radius" (radius of a cylindrical tool) that occurs in blade processing is not generated.

This makes it possible to reproduce the microscopic shape of organs.

-

Silicone

Materials from a variety of domestic and overseas manufacturers can be used. In addition to the characteristics of high transparency and low hardness, it is possible to adjust the hardness by using silicone thinner.

For some silicones, it is possible to add more than 50 wt% thinner, but this will significantly reduce the physical properties, resulting in poor curing or thinner components bleeding onto the surface.

-

Polyvinyl alcohol(PVA)

The material itself, called hydrogel, contains water, so it has good wettability and slipperiness, and feels very close to the organs of the human body.

-

Urethane foam

It can reproduce both low and high hardness, which is similar to the touch of human skin.

-

Ultrasonic compatible materials

Materials that can be captured on an ultrasound imaging system can be used.

-

Cutting materials

Materials such as acrylic, ABS, polycarbonate, and polypropylene can be used.